How to Setup Woodwork Shop | The 3 Most Common Mistakes | Check Video Below

Introduction To Setup Up Woodwork Shop

In the context of a wood shop, you will be using tools and machines to make items out of wood. You can also use this space for other projects like making furniture or cabinets. There are safety precautions that need to be taken into account when doing any types of work in this type of environment as well as proper equipment such as gloves, goggles and earmuffs which should always be worn when working with power tools at home or in business premises. A good rule is always to follow the rules according to your country’s regulations regarding workplace safety standards so that everyone involved in your project gets along well together without any problems arising later on down the road when things go wrong due to lackadaisical attitude towards safety measures taken by all parties involved during construction phases leading up until completion dates set by clients themselves (or owners).

The ground floor layout should include:

- An entrance way leading into main workshop area where employees enter through doors located near entrance points located either side walls opposite each other; these doors open outwardly onto working surface area where workers sit down while doing their job duties making sure they don’t get hurt while doing those tasks over there because if something happened then nobody would want anything bad happening either!

“Discover The 3 Most Common Mistakes When Setting Up Your Shop & How You Can Avoid Them”

Turn on your speakers & watch the video below:

Tools and machines

The tools and machines are important for woodworking. These tools are used to make the work easier and faster, while machines help in making the work more accurate.

Tools:

- Marking gauge – This tool is used to mark the outline of a board on which you will be cutting later on in your operation using a router or saw. It has two sides with different sized notches on each side so that it can be set up at any angle without changing its size or shape when placed against something else. You should never use this type of tool if there is no need because it might damage your hand or fingers when trying to hold onto it for long periods of time due to its large size and weight; instead, use another method like pencil marks made directly onto wood before starting any project (this works best if done before cutting).

Safety precautions

- Use safety equipment.

- Use safety precautions.

- Use safety equipment to prevent accidents and injuries, fires, electrocution and burns.*

Safety equipment

Safety equipment is a must. Here’s the list of things you should have on hand:

- Safety glasses and earplugs. You will be exposed to some serious fumes, so make sure your eyes are protected by goggles or safety glasses. You’ll also want to protect yourself from dust and debris with earplugs, which can block out loud noises while keeping sound in so that you’re not overwhelmed by all the noise around you (which could lead to injury).

- Work gloves and work boots. For protection against nicks and cuts from sharp tools or other hazards, wear leather work gloves and heavy-duty steel toe shoes with rubber soles if necessary; these items help protect against slips on wet floors as well as falls off ladders or scaffolding structures during construction projects!

The shop floor layout

The shop floor layout should be designed to suit the needs of the woodworker. The layout should allow easy access to all parts of your shop, including the woodworking equipment, so that you can perform any task with ease.

3 Most Common Mistakes

The most common mistakes are:

- Making the shop too small. This is a big mistake, as it will make you have to move tools and machines around all the time. You should also make sure that your shop is well ventilated so that things don’t get too hot or cold in there.

- Not having enough space for the tools and machines. If you can’t fit everything in one spot, then organizing them properly becomes very important! Try not to overload yourself by putting too much stuff into one area; instead spread out your equipment across multiple areas of your shop until everything finds its own place where it can be easily accessed by any worker who needs something from it (or even just looks at it).

- Not having enough space for safety equipment such as goggles or earmuffs because these things get lost easily when moving from one place to another; this could result in serious injuries if someone trips over something while wearing them! Make sure there’s always some kind of protective gear nearby so everyone knows what steps need taken before moving around safely again after doing work outside during bad weather conditions like windy days.”

How much money do I really need

How much money do you really need?

It’s a good question, and one that we’ll answer in this article. In order to setup your own woodwork shop at home or in your garage, there are several factors that need to be considered:

- The cost of the equipment needed (ie saws, sanders etc)

- The cost of building materials (ie lumber)

- Cost of electricity bills for running the tools

How do I avoid bad quality tools in woodwork shop

- Choose the best tools for the job

- Choose the best quality tools

- Choose the best quality materials

- Choose the best quality equipment

- Choose the best quality safety gear and equipment

What are the critical factors in setting up woodwork shop

- Location: It is the most important factor in setting up woodwork shop.

- Size: The size of your woodworking shop should be based on the size of your budget and the equipment you need to buy.

- Equipment: The equipment needed for woodworking are tools, power tools and hand tools that can help you create things like furniture or other types of items such as home decor items etc.. Safety is very important so make sure you have a safe working environment in which nobody gets hurt during any operation done inside it (including yourself). Safety equipment includes masks etc…

- Layout : Layout refers to how everything will look when someone walks into this area where he/she will see all those bins filled with sawdust lying around everywhere which means one thing – there’s no space left for anything else! This can lead to accidents if not kept under control with proper precautions taken beforehand.”

How much money do I really need to setup wood workhop

How much money do I really need to setup wood work shop?

The answer is simple: you need to know your budget, and then work around it. If you are starting off on a small scale, then yes, it will cost less than $1000 in total expenses. But if you’re planning on opening an entire store with multiple employees and multiple branches, then this number could get higher by thousands of dollars depending upon where in the world you want to open your business (more on this later).

However one thing that must be kept in mind while deciding upon how much funds should be spent initially is that once everything has been set up properly there shouldn’t be any additional expenses apart from regular maintenance costs – which can vary significantly depending upon what type of material was used during construction process as well as other factors such as weather conditions outside etcetera.

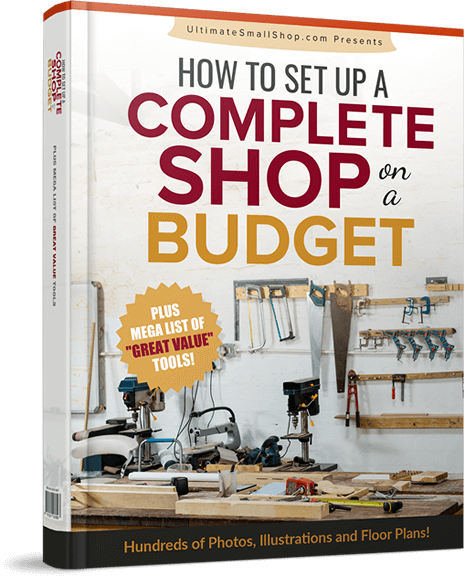

The Ultimate Small Shop Guide

How to set up a complete small workshop on a budget